A ship is subjected to stresses from a complex system of forces and the structure must be braced and supported to withstand any reasonable combinations of load at a given time. The cost and weight in the construction of a ship must be balanced against strength, rigidity, sea worthiness and cargo capacity. The structure of a ship is subject to two basic types of force, namely Static and Dynamic forces. The former is produced by gravity, ie the forces exerted by weight and water pressure. The latter are produced by such actions as rolling, pitching and heaving.

Longitudinal stresses.

There are four main types of longitudinal stresses:

-

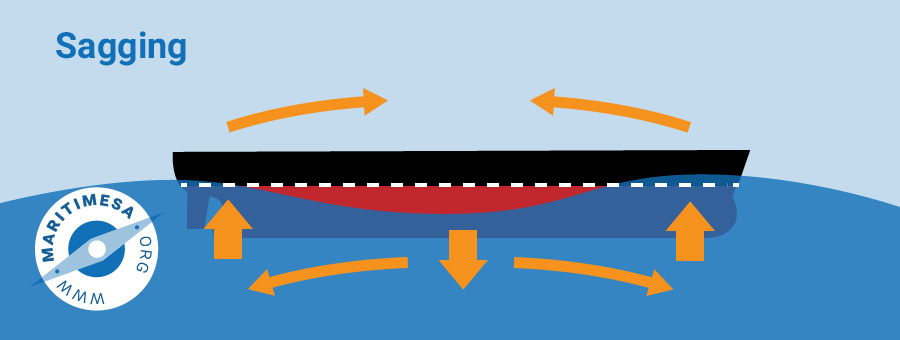

- Sagging. Sagging stresses are caused by the uneven distribution of weight and buoyancy in the length of the hull. If a ship is supported on either end by the crest of a wave, the stress exerted by the waves on the buoyancy of the vessel would tend to lift the ends, whilst the centre of the vessel would suffer a loss of buoyancy and tend to sag. This type of stress is known as sagging.

- Hogging. When the wave passes the reverse situation results, ie the middle of the vessel is supported on the crest whilst the two ends hang over the crest on either side. This action is known as hogging.

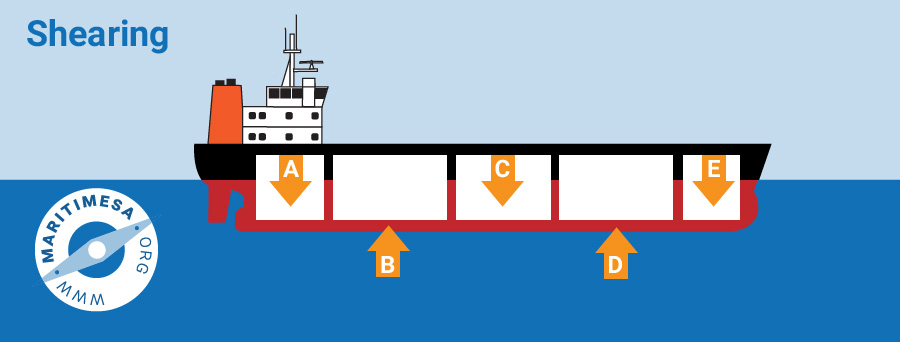

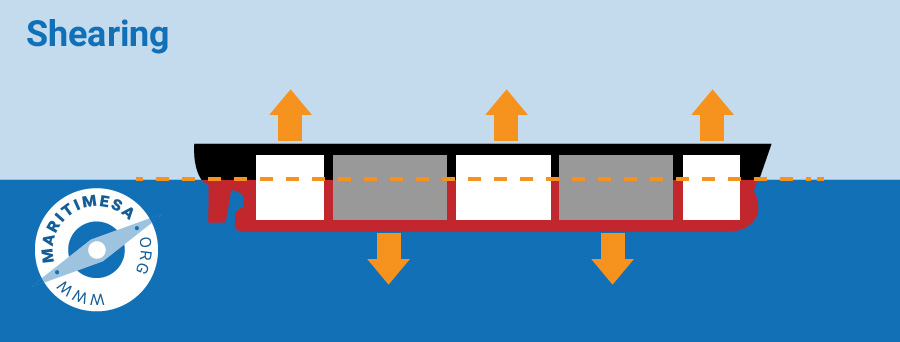

- Vertical shear forces. Because a merchant vessel has a number of compartments along the length of the hull, there may be a difference in the loading of these compartments. The forces of gravity and buoyancy would then tend to differ from compartment to compartment and where transverse bulkheads are situated one would experience vertical shear forces. This would be particularly so when one compartment is empty and the other next to it is loaded.

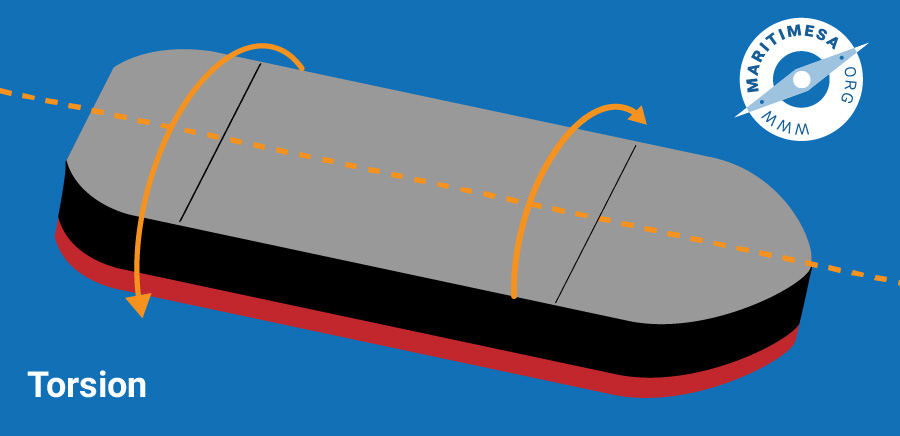

- Torsional forces. If a vessel is subjected to pitching and rolling at the same time, ie taking the wave on either bow, the vessel tends to twist longitudinally. These are known as torsional stresses or forces.

- Sagging. Sagging stresses are caused by the uneven distribution of weight and buoyancy in the length of the hull. If a ship is supported on either end by the crest of a wave, the stress exerted by the waves on the buoyancy of the vessel would tend to lift the ends, whilst the centre of the vessel would suffer a loss of buoyancy and tend to sag. This type of stress is known as sagging.

Transverse stresses.

There are three main types of transverse stresses:

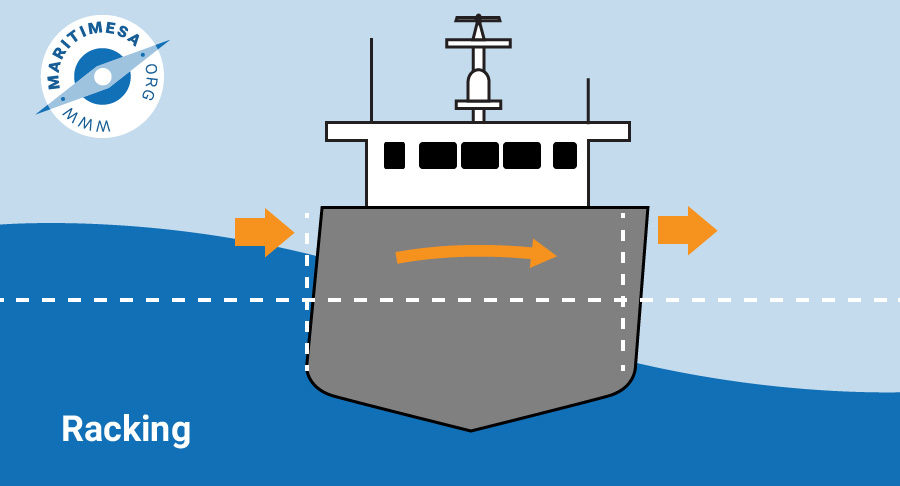

- Racking. When a vessel is rolling in a seaway the transverse section will try to distort at the corners due to racking stresses.

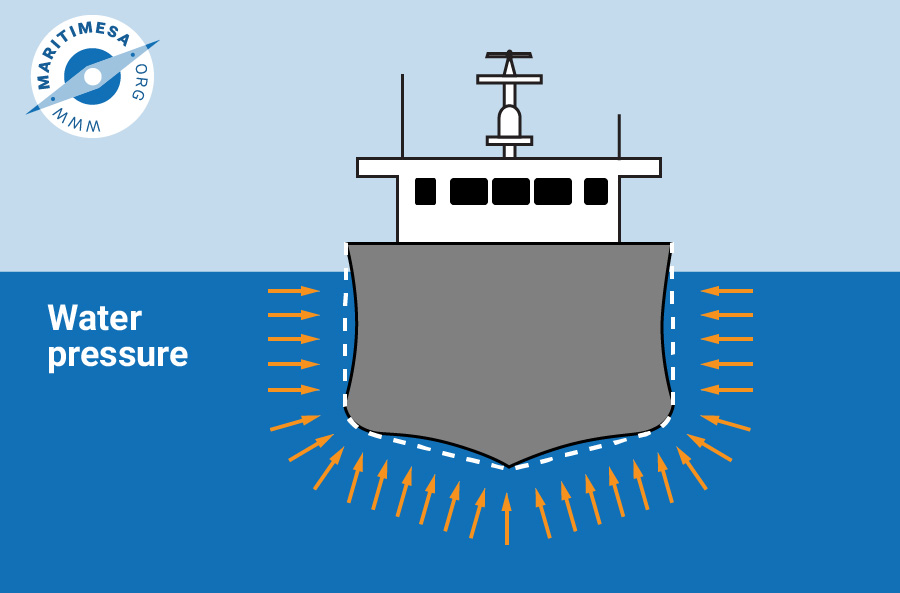

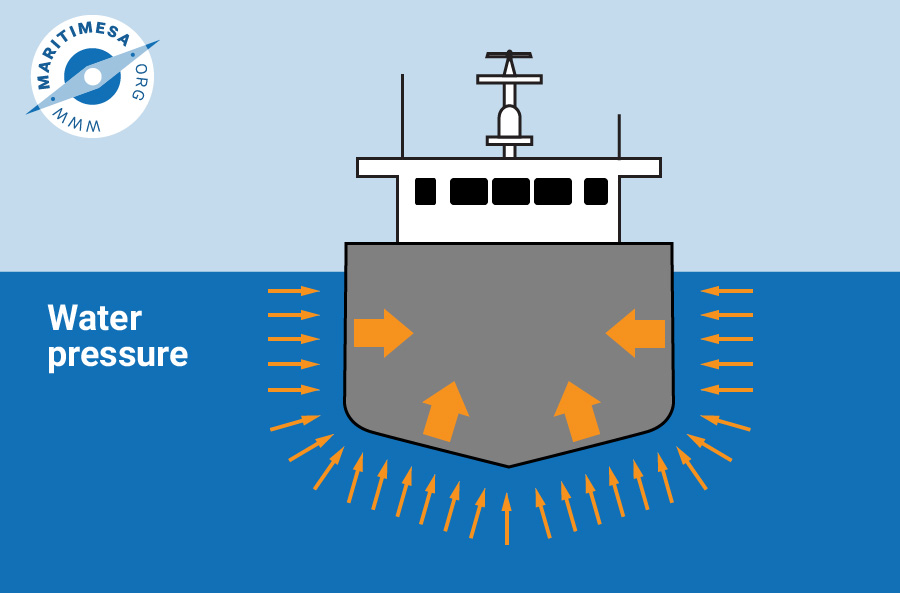

- Water pressure. Water acts perpendicular to the surface of the submerged hull and increases with depth. This produces collapsing stresses which must be resisted.

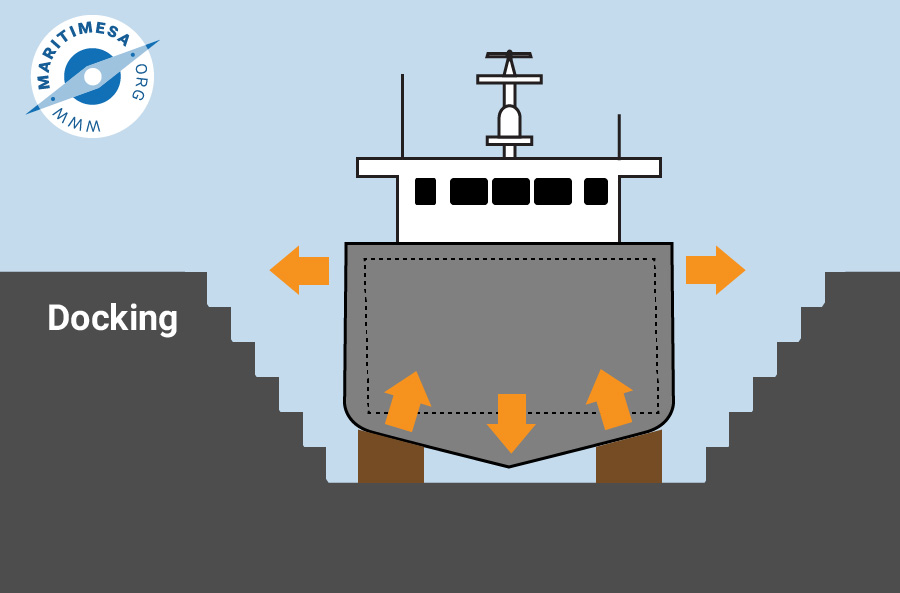

- Docking stresses. When a ship is drydocked the thrust from the water is removed. The hull on either side of the keel strake tends to sag downwards and the beams are in tension. Keel blocks, bilge blocks and side shores are needed to support the ship. The arrangements of keel and bilge blocks are different for each class of ship. Side shores (wooden baulks of timber) also differ from ship to ship.

Local stresses.

Again there are three main types of local stress:

- Panting. When the ship is under way in a seaway, she is subjected to changes in pressure caused by the waves and the pitching if the ship. The variation of pressure at the ends causes the ship to vibrate due to panting stresses. Panting has a concertina type of effect on the hull.

- Pounding. As the ship pitches into a head sea excessive pounding may occur in the forward section of the hull if the vessel is not fully loaded.

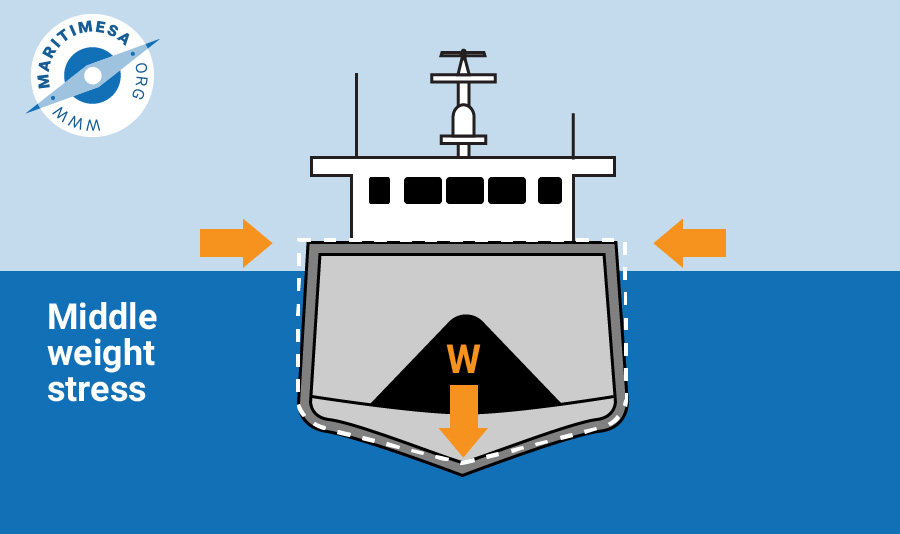

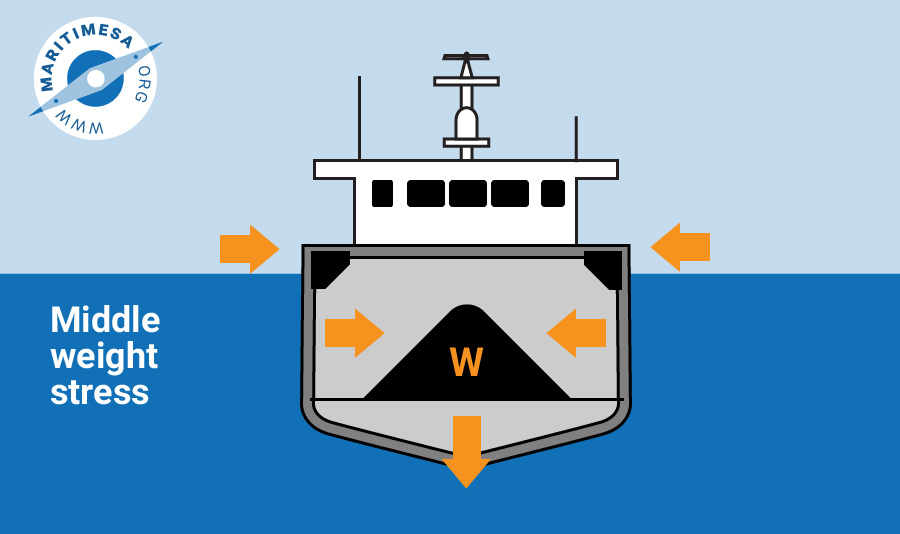

- Middle weight stresses. The concentration of heavy weights along the centre line of the hold causes the sides to tend to collapse inwards.