Because they are exposed to salt water and salt water spray, ships need constant maintenance to prevent serous corrosion of the steel from which they are made. If corrosion is not checked, steel plates or steel “ribs” will weaken and could be seriously damaged by the sea, with possible loss of life or loss of the ship.

Onboard maintenance continues every day with teams or individual crewmembers chipping away rust and painting the steel. Most good companies have a planned maintenance programme whereby every part of the ship is maintained over a period of time. Sometimes “riding squads” (teams of painters or engineers or technicians) board the ship in a port or between ports to assist the crew with the maintenance of the ship.

Special maintenance projects, such as the periodic drydocking of ships, are also undertaken. These usually coincide with annual surveys of the ship or special surveys as done by the ship’s classification society and/or the authority of the country where the ship is registered.

Drydock

A drydock is a facility (usually in a harbour) used for underwater work (painting the bottom part of the ship; checking propeller shafts, or repairing parts of the ship that are normally submerged. A drydock has a removable watertight gate (or cassion). When water levels inside and outside the drydock are the same, the cassion is removed and the ship is floated into the drydock. The cassion is then replaced at the entrance to the drydock and the water is pumped out. As the water level goes down, the ship settles on large blocks that have been placed in special positions according to the length, beam and structure of the ship. Once all the water has been pumped out, the maintenance teams can work on the bottom of the ship, check eh propeller shaft, rudder or do whatever other tasks to which they have been assigned.

When the work has been completed, water is allowed to flow in a controlled manner into the drydock, the ship floats, and once the water levels inside and outside the drydock are the same, the cassion is removed and the ship can be taken out of the drydock.

In South Africa, drydocks are situated in Cape Town (Sturrock Drydock –the largest in the southern hemisphere and in Africa; Robinson Drydock, the first to be built in southern Africa); Simon’s Town, East London and Durban.

The LNG Carrier Al Marrouna in drydock. Note the blocks on which she is resting. The anchor chain has also been lowered for checking and to paint the various “shackle lengths”. Note the bow thruster which is visible next to the anchor chain. Note also her bulbous bow. Photograph: Teekay

The shuttle tanker Navion Scandia in drydock. Note her twin propellers and twin rudders which are necessary when she maneuvers to couple up to an offshore oil facility to load crude oil. Photograph : Teekay

Synchrolift

A synchrolift is designed to lift smaller vessel out of the water so that underwater repairs and maintenance can be done. When the work has been completed, the vessel is lowered back into the water. In South Africa, synchrolifts are located in Cape Town, Simon’s Town and Durban,

Cape Town’s synchrolift is shown in the centre of this photograph. One vessel (black hull and blue deck fittings) is about to be lifted. Four others (stern-on to the camera) are already on the hard, undergoing refits. Photograph : Brian Ingpen

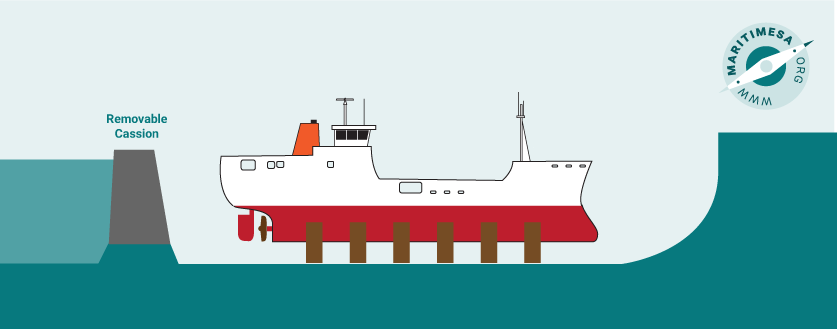

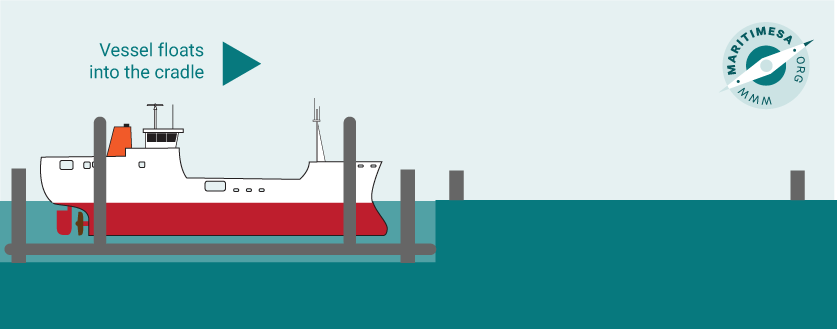

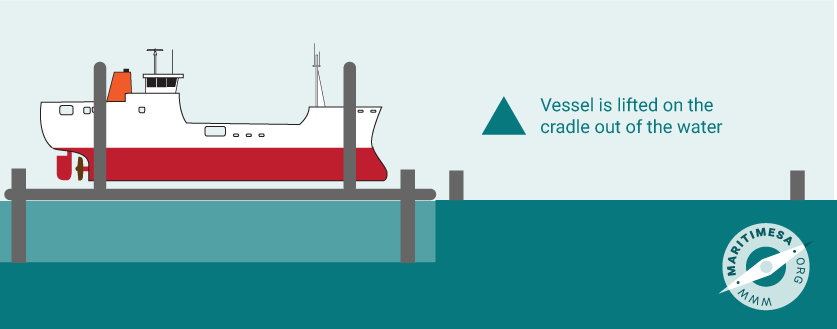

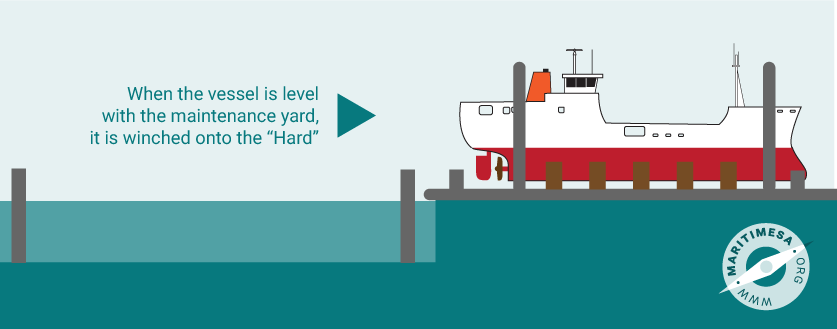

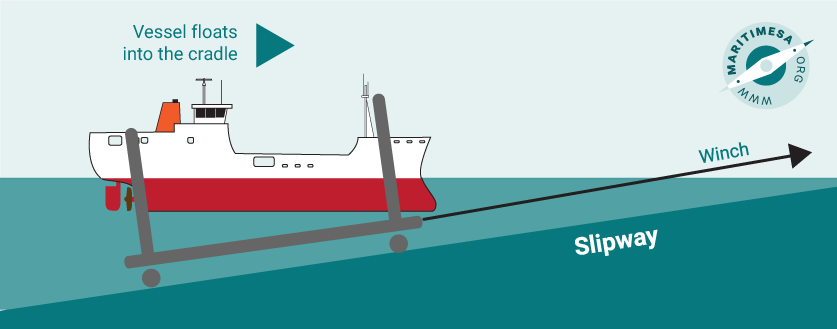

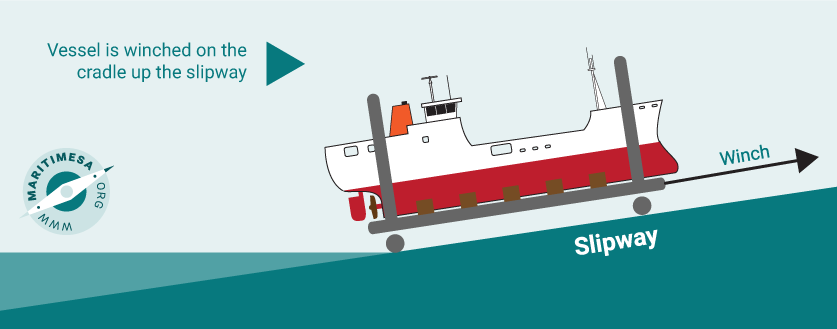

Slipway

A slipway is an angled facility where smaller vessels can be placed on a cradle and winched out of the water for underwater repairs and maintenance. Most large harbours and smaller fishing harbours and yacht marinas in South Africa have slipways to repair small fishing vessels and leisure craft.

Floating Dock

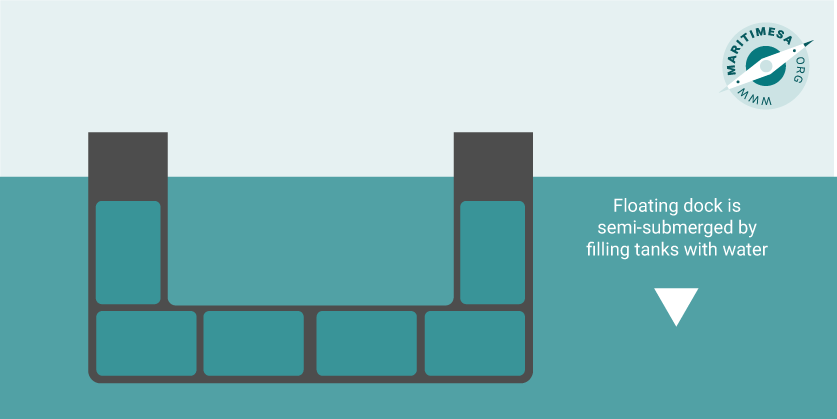

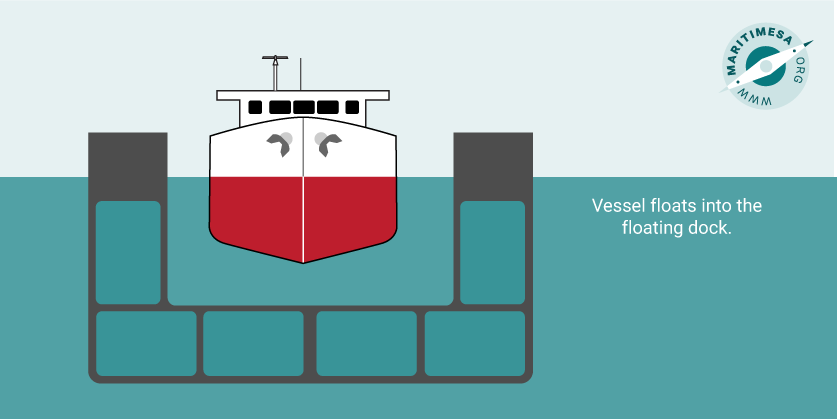

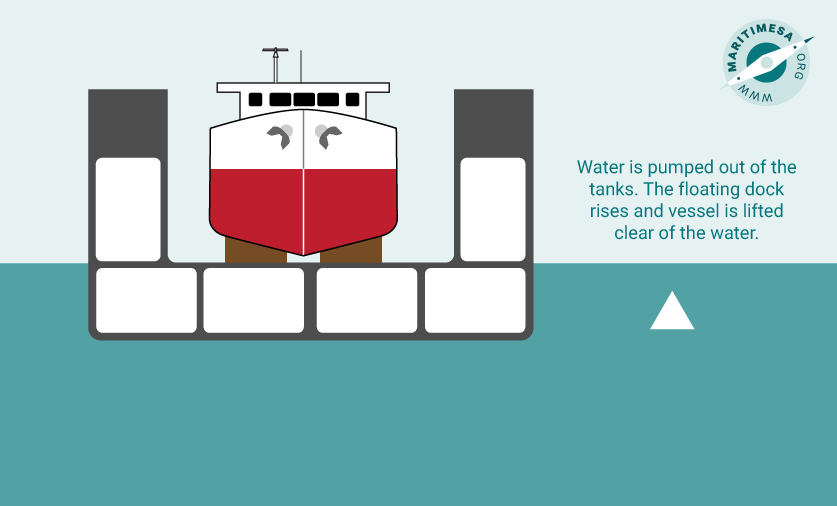

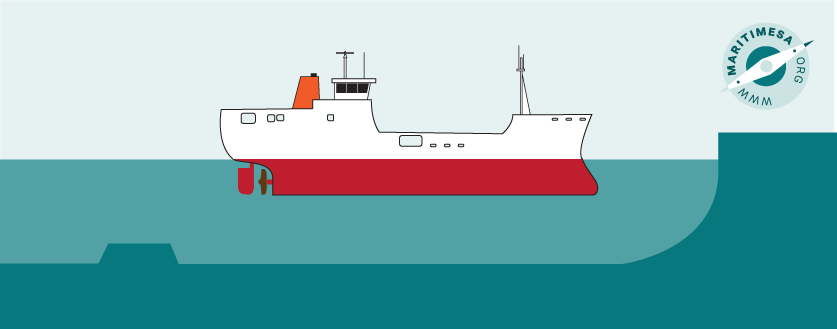

A floating dock is a structure which has large tanks that, when filled with water, cause the dock to semi-submerge. The vessel can then be floated into the dock, the water is pumped out of the tanks, and the dock rises. As the dock rises, the vessel settles onto pre-arranged blocks. Once all the water has been pumped out of the tanks, the ship is clear of the water and work can begin on repairing and maintaining the underwater parts. Once the work has been completed, the tanks are filled with water, the dock is semi-submerged and the ship can be floated out of the dock.

Durban has a floating dock and Walvis Bay has three.