[vc_row][vc_column][vc_video link=”https://vimeo.com/522359010″][vc_column_text]

The building that houses Cape Town’s Port Control Office (the glassed area near the top of the tower) as well as the offices of the Harbour Master, Harbour Manager and several other administrative functions.

A harbour for merchant ships usually has two divisions :

- The Marine Division is responsible for the safe movement and mooring of ships as well as marine services in the harbour such as vessel control, pilotage, tug services, drydocking, bunkering, harbour security, buoyage and other navigational aids.

- The Harbour Management Division is responsible for the administration of the harbour, all the land area belonging to the harbour, harbour equipment and machinery, harbour buildings, the financial management of the harbour, and the marketing of the harbour.

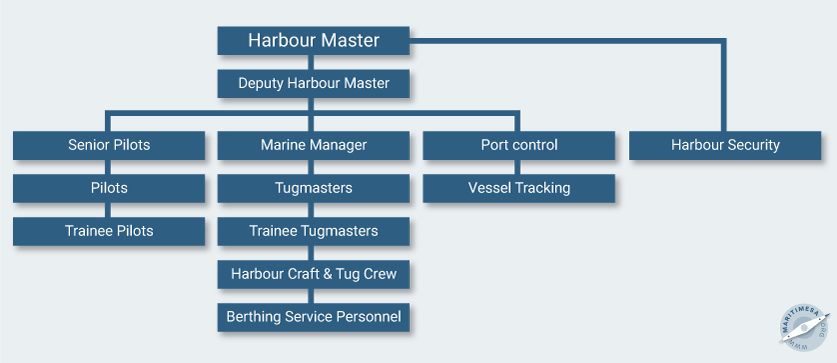

The typical rank structure of the marine division of a harbour is as follows :

Note that the structure may vary according to the size of the harbour, the number of ships calling, and the particular requirements of the harbour. Some harbours, for example, have environmental officers as well.

Procedures, personnel and vessels involved in ships’ movements in harbours and drydocks and locks.

A ship arriving in a harbour

A ship has signaled the harbour’s Port Control that she will arrive off the port at 0600 on a particular day. (This is her Expected Time of Arrival – her ETA.) This is the time that she will arrive at the Pilot Station, a position (not an actual structure) a mile or two off the harbour’s breakwater. Boarding the ship at that position is a harbour pilot, an officer who is appointed by the harbour to assist the ship’s master (the captain) to bring the ship into port.

She will have confirmed her ETA the previous evening and Port Control will have confirmed that her berth will be ready for her on arrival. (If the berth was occupied, Port Control would have informed the ship that she will probably have to anchor on arrival to wait for the berth to become available.)

The following are the usual procedures that occur as the ship approaches the harbour. (Times will vary according to the harbour’s location and actual operating procedures.)

- 03:00 Ship confirms her ETA as 06:00. Port Control requests that she informs it when she is four miles away from the pilot station.

- 04:30 Ship confirms that she will be at the pilot station at 06:00. If the ship’s berth is available, Port Control acknowledges the information and calls up the harbour tugs, the pilot and the launch (or helicopter) to carry the pilot to the pilot station. The berthing services will also be called to help moor the ship at the berth. The pilot prepares to go to the ship; the pilot launch leaves to pick up the pilot at the usual place in the harbour; the tugs prepare to leave harbour to assist the ship. (The berthing services team will leave their base a little later.)

- 06:00 The ship arrives at the pilot station. She has a pilot ladder rigged on her lee side. The pilot launch comes alongside the ship and the pilot boards. The tugs prepare to make their towing line fast – one tug at the bow; the other at the stern. The tugs may have to turn the ship, slow her down or push her gently against the wharf.

- 07:00 With the pilot on board and the tugs in attendance, the ship approaches her berth. Mooring lines are put ashore and made fast to bollards on the wharf.

- 08:00 With the mooring lines secure, the tugs are released and the pilot disembarks from the ship.

- Later Once certain clearances have been done (see Grade 11 section), the ship can begin her cargowork and/or bunkering and/or other operations.

A containership being turned by a tug so that she can berth starboard side to, an expression that means that her starboard side will be against the wharf. The second tug is partly obscured by the ship.

A ship sailing from a harbour:

The ship (or her agent in the port) informs Port Control of her Expected Time of Departure (her ETD). The ETD will be amended if necessary during the ship’s stay in the harbour. Once the ship’s ETD can be confirmed (e.g. 23:00), Port Control are informed.

- 22:00 Port Control calls up the harbour tugs, the pilot, the pilot launch and berthing services to prepare to sail the ship. The ship also prepares to sail and her crewmembers go to “stations” – i.e. on the bridge are the master, chief officer, chief engineer (who will control the engines from the bridge), a helmsman who will steer the ship in response to orders given; some deck ratings go the fo’c’sle and some to the stern to release the mooring lines. (Engineers will have been at their station in the engine control room well before sailing time to start the main engine and to conduct a number of tests of machinery.)

- 22:30 The pilot boards and discusses the sailing operation with the ship’s master; the tugs connect their towing lines (one tug at the bow and the other at the stern); the crew begin to “single up”, i.e. to let go all mooring lines except one forward and one aft. NB: When under pilotage in most harbours, the ship remains under the master’s orders, and to the pilot’s advice. This means that the master remains in command of the ship (and responsible for everything that happens) while the pilot advises him/her and passes orders to the tugs.

- 23:00 If everything is ready, the pilot orders the tugs to start pulling the ship from the berth. He may also order them to turn the ship if necessary so that she can leave the harbour.

Once the ship is lined up for the harbour entrance and is in teh channel leading to the sea, the pilot leaves the bridge and prepares to disembark via a pilot ladder to the pilot launch that comes alongside (or a helicopter may lift him/her from a a clear part of the ship).

As the ship leaves the harbour and increases speed for her voyage to the next port, the tugs return to their berths, or prepare to assist the next ship entering or leaving the harbour.

A containership sailing from Cape Town. Note the pilot launch alongside, waiting for the pilot to disembark.

Drydocking

A drydock is an area in a harbour that can be sealed off and the water pumped out. All ships need to be drydocked periodically so that underwater maintenance, repairs or mandatory surveys can be done. Before drydocking can happen, the blocks on which the ship settles need to be arranged to fit the design of the ship that will be drydocked.

The ship enters the drydock, the gate is placed in the entrance to the drydock, the water is pumped out, and the ship begins to settle. Once all the water has been pumped out, the ship rests on blocks at the bottom of the drydock, and work can begin on the ship.

When the ship is ready to leave the drydock, water is allowed to flow into the drydock in a controlled manner. As the ship begins to float, checks for any leakage are made at crucial parts of the ship. When she is fully afloat and the water levels inside the drydock and outside are the same, the gate can be removed, and the ship can leave the drydock. Tugs usually assist a ship into or out of drydock.

The heavylift ship Mighty Servant 3 in drydock. Note how tightly she fits into the drydock, making her entry to the drydock or her departure from the drydock a very difficult procedure that requires careful planning and execution by the ship’s master and the pilot. Photograph: Andrew Ingpen

Synchrolift

A synchrolift facility lifts smaller vessels out of the water and moves them up onto a wide area where the ships are repaired, maintained or surveyed. Cape Town, Simon’s Town and Durban have synchrolifts.

[/vc_column_text][/vc_column][/vc_row]