Cargo working gear consists of shackles, cranes, derricks and their associated equipment, masts and Sampson posts and the wires/ropes used to connect them all together.

Shackles.

Types:

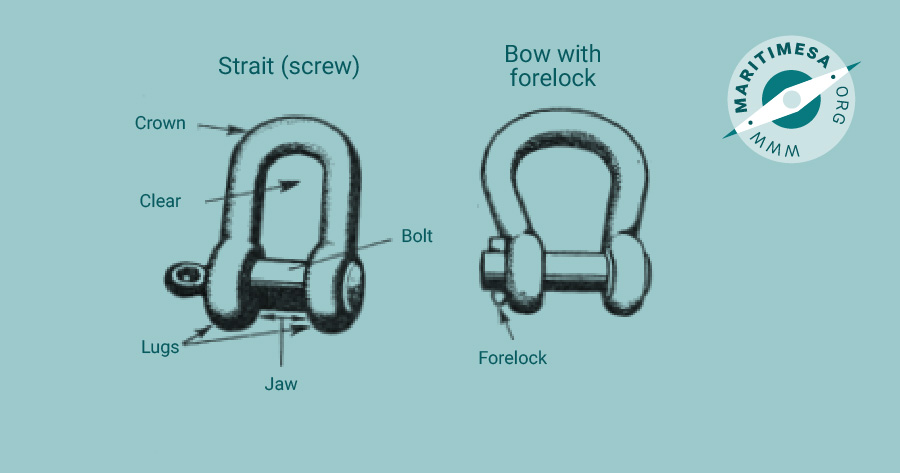

Shackles are named according to their different shapes, ie “D” or “Straight backed”, “Bow” or “Harp” shackles. One other type which is not used in cargo work is called the “Lug-less shackle” and is only found in anchor cables.

Left shackle is a “D” shackle, right shackle is a “bow” or “harp” shackle.

Shackle with a fore lock.

When using a fore lock shackle, always make sure that the forelock is facing the jaws and that the pin is opened up so as to prevent the pin from coming out. They should not be used with running gear.

Shackles should always be tested, at least once a year by a competent person, and their safe working load (SWL) must never exceed half the proof load. The SWL must be clearly stamped onto it, and the Test Certificate must be kept in a safe place where it is readily available.

Before using a shackle, it must be “moused” with wire, so as to prevent the pin from unscrewing with possible disastrous results.

Derricks and cranes.

Cranes.

S.A. Agulhas 1 with large crane situated forward.

Derricks.

Ship fitted with derricks.

Derricks are the cheapest and quickest means of working cargo. Their operators do not have to be as well trained as crane drivers. They should be topped up as far as possible with regard to the positions of the cargo. A derrick that is near to the vertical can take a much bigger load than a derrick which is near the horizontal.

With both cranes and derricks, fast hoisting and lowering and sudden jerks on the runners imposes a great strain not only on the runner, but on the whole equipment which can cause some part of it to fail.

Every part of the cargo gear must have its SWL stamped on it, or have a Safety Certificate, this includes the wires being used.

Derrick systems.

There are a number of different systems of using derricks. For example there are Swinging derricks, Dead man derricks, Yo-YO derricks and the Liverpool method.

However, the most usual means of handling cargo with derricks is by means of the “Union Purchase” method, where two derricks are used together. If as is usual, the derricks SWL is 5 T, then the two together can lift up to a maximum of 3.5T, but the usual lift is around 1.5 T.

Union Purchase Method.

The two derricks are rigged so that one will be overboard and the other will be over the centre of the hatch. Their runners are joined together as shown in the below drawing. This method is designed to prevent undue stress on the joining shackle when the runners are stretched. The load is first hoisted by one derrick with the other derrick’s runner being slack. Once the load is clear of the hatch coaming or bulwark, the previously slack runner is tightened up and pulls the load across, hoisting as necessary to keep the load clear of obstructions. The other runner then starts slacking away slowly till the other derrick has the full weight and the load is ready to be lowered. It then gives full slack till the load has been lowered into position.

Union Purchase Method

Cranes vs Derricks.

Advantages of using derricks:

- They are relatively cheap and uncomplicated.

- They are fast.

- They do not require skilled labour to operate.

Advantages of using cranes:

- They can hoist and land cargo from any spot within range of the crane.

Disadvantages of cranes:

- They cost a great deal.

- Speed of handling.

Care of cargo gear.

It is essential that the cargo gear is inspected and maintained on a regular basis. Items to be considered and actions to be taken are the following:

- All cargo and running rigging must be oiled and greased regularly. The cargo gear should always be checked and overhauled while the ship is at sea. All the gear must be carefully checked and refitted as necessary. The derricks’ goose necks should be lifted and greased occasionally. When proceeding on a long voyage the gear should be taken down and stowed away carefully.

- All wires must be inspected regularly for kinks, flattening, wear and broken wires.

- All cargo gear must be tested regularly and have their SWL stamped upon them.

- All shackles, blocks and runners in the cargo gear must be of the same SWL.

- Weather, type of cargo and the amount of deck cargo carried will influence what work can be carried out on the McGregor hatches.

- If heavy weather has been experienced, then the hatches should not be touched until alongside, and a Cargo Surveyor has been down to examine them.

- Derricks must be topped up and made ready for work before entering harbour, weather permitting. The pins of all shackles must be “moused”.

- The derrick must never be overloaded.

- All guys must be heaved up tight when working cargo.

- Preventer guys must be rigged when the derrick is being used close to its maximum SWL.

- The runners must be of sufficient length to reach the furtherest point that the derrick can reach, and still have a minimum of at least 6 full turns on the winch barrel.