Before a rope is used one should always ensure that the ends are whipped. This prevents the ends

from turning into “horses tails” and starting to unravel. It also makes the rope more seamanlike and neater.

A whipping should always be at least equal in length to the diameter of the rope being whipped.

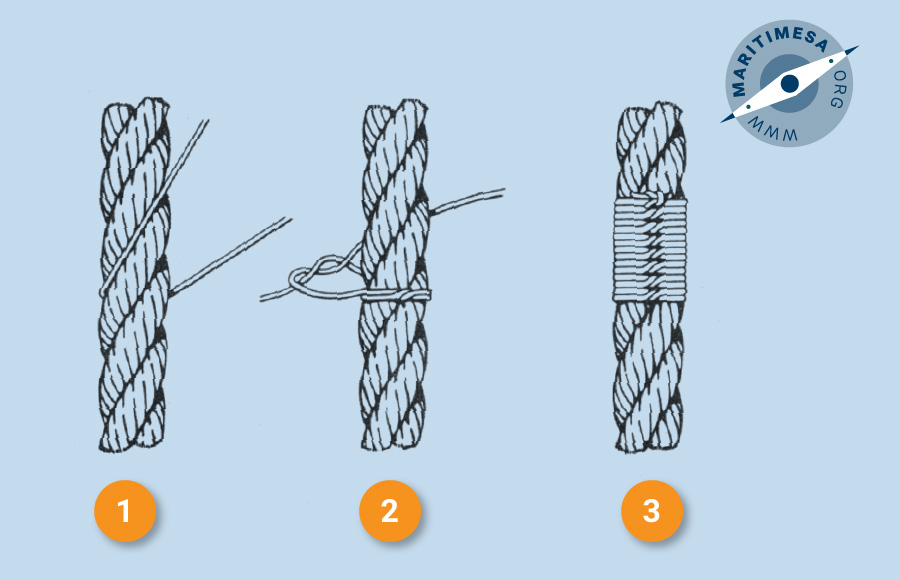

Common whipping. Rope twine is used to whip a rope when it is not large. Place the end of the twine along the rope as indicated in the figure (i). Pass the turns of the twine over the rope against its lay, working towards the end of the rope and pull each turn taut. Then lay the other end of the twine along the rope, as indicated in fig (ii) and pass the remaining turns over it, taking the bight of the twine over the end of the rope with each turn. When the bight becomes too small to pass over the end of the rope, pull this second end of the twine through the turns which you have passed over it until taut. This completes the last turn of the rope and the end should be cut off. See figures(iii) and (iv).

Common whipping.

Linesman whipping. A linesman whipping is a very quick and practical one but is unsightly. It can be sued on any type of rope, but it is used on synthetic ropes mainly. It consists of insulation tape the end of which is placed under a strand of the rope and then simply wound around the rope.

West country whipping. This consists of a series of half knots tied on either side of the rope and ended with a reef knot.

West country whipping.